-

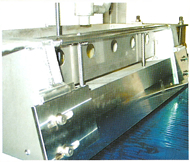

Overflow Feeder

Molten materials with low viscosity are supplied to the steel belt in fixed volumes via the feeder. The product flows over the horizontal gate and onto the belt with a uniform thickness and width. -

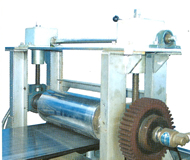

Single-axis Press Roller

This Press Roller supplies low and medium-viscosity materials that cannot be supplied using an overflow feeder.Water is fed through the inside of the roller to prevent the product from sticking. The surface finish and roller material can be selected according to the materials being handled. -

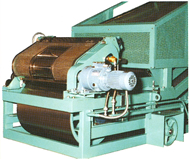

Double-axis Press Roller

This unit is ideal for rolling high-viscosity materials using an extruder, for example on production lines for powdered paints or toners.

Granulator

"Granulators" use a specialized feeder to extract the product in granular form. They are unique in that the product does not have to be crushed after it has been removed; the particle size is uniform, and no dust is generated. A further advantage of this uniform particle size is that when the material is melted to form the secondary product, it melts easily at a fixed temperature. By combining this granulator with the Steel belt cooler, it becomes possible to produce large volumes of highly consistent particles.

Crusher

The Crusher takes the product that has been formed into a sheet by the belt cooler or other cooling device, and crushes it into a fine powder. There are numerous other crusher types intended for different materials and applications. The photo on the left is a Pin Rotor Crusher. Because this Crusher is often used to handle various types of materials, it is designed to enable internal components to be cleaned very easily. Models with abrasion-resistance finish and replaceable pins are also available.